WORKFORCE CONTINUITY ARCHITECTURE FOR INDUSTRIAL-BASE READINESS

Stabilizing Skilled Labor for Submarine and Shipbuilding Programs

Shipbuilding and sustainment depend on continuity in critical skilled roles. Attrition rates of 20–22%—and 30% in high-demand billets—continue to disrupt production tempo. Schedule delays in prior years highlight the need for a continuity architecture that protects output, delivery, and readiness.

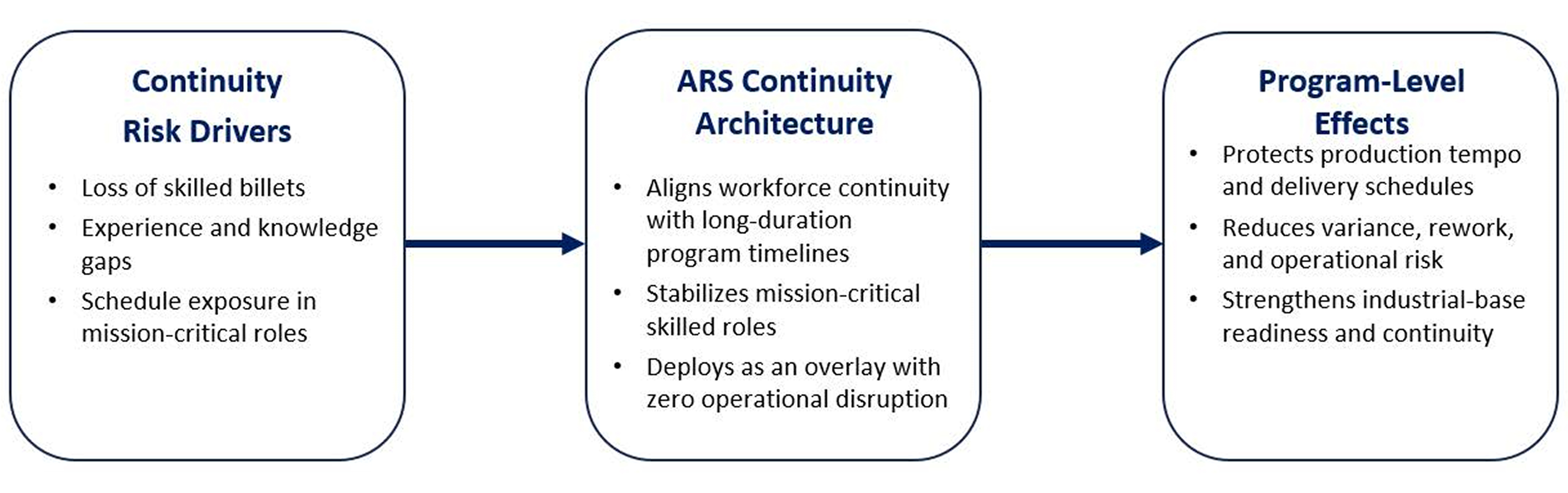

THE OPERATIONAL REALITY

Recruiting and training have expanded the pipeline. Continuity has not kept pace. The result is recurring workforce loss, requalification cycles, and schedule variance across successive production years.

The effects are consistent:

Loss of skilled billets interrupts delivery.

Experience gaps add scheduling and onboarding demand.

Slippage compounds across production cycles.

Continuity has become the limiting factor for throughput and execution.

CAPABILITIES

Continuity architecture for submarine and shipbuilding programs

Protects delivery timelines for critical billets.

Stabilizes multi-year skilled workforce assignments.

Supports sustained production output across program phases.

Industrial-base readiness support

Reduces workforce-driven schedule variance.

Stabilizes mission-critical technical roles.

Maintains continuity across execution cycles.

TEAMING AND PROGRAM ALIGNMENT

Primes and Shipyards

Program authority

Production cadence

Delivery requirements

David Alemian, Inc.

Continuity framework design

Stability modeling

Sustainment metrics

DISTINCT APPROACH

Aligns workforce continuity with program timelines and service requirements.

Integrates without disruption to existing authority or workflows.

Designed for uninterrupted execution environments.

STRATEGIC ENGAGEMENT

Engagements begin with a continuity and workforce architecture assessment tied to program timelines and critical billets. The objective is to identify where instability introduces risk into production, sustainment, and delivery schedules.

The outcome is a continuity model aligned to program execution requirements.

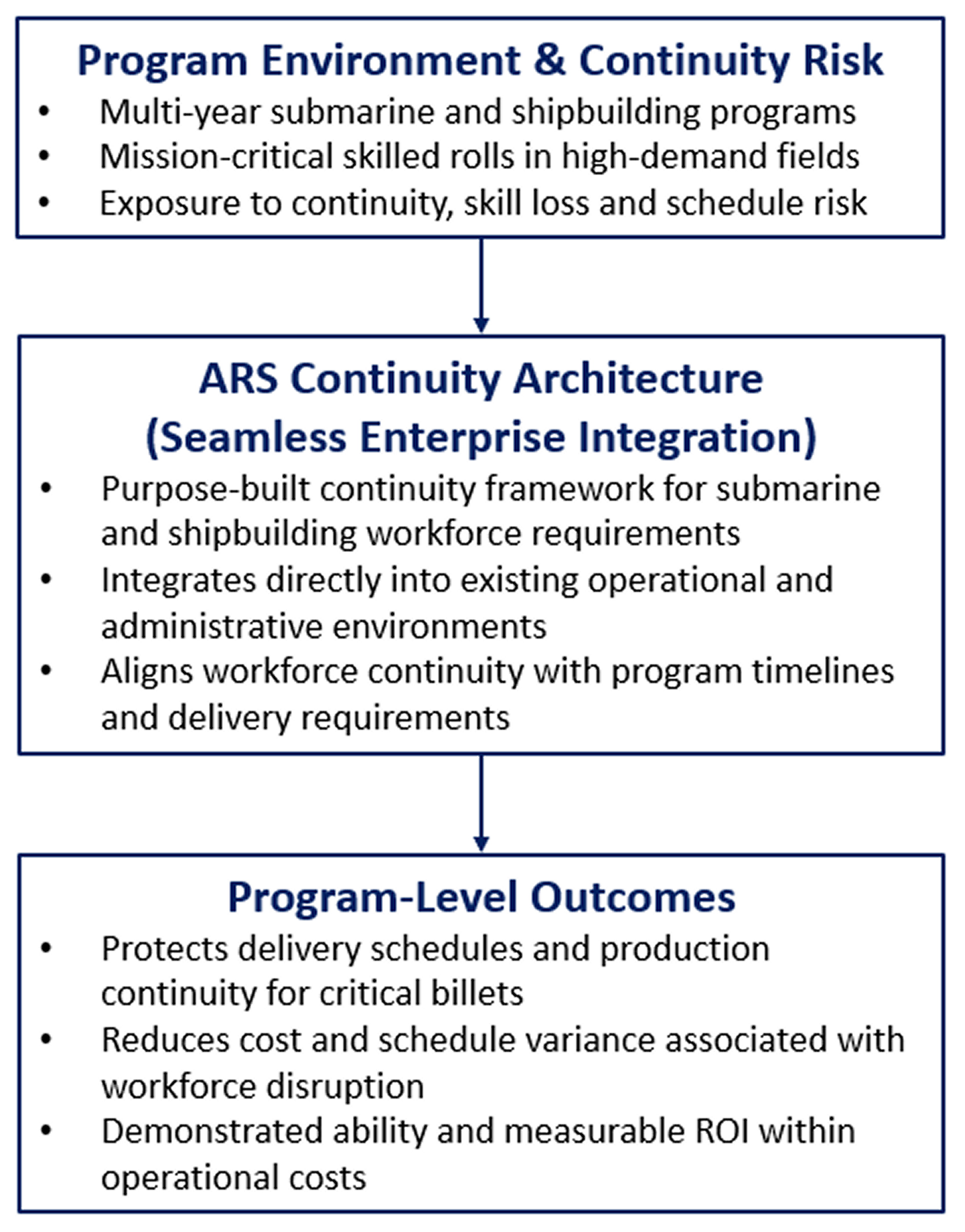

THE ALEMIAN RETENTION SYSTEM™ (ARS)

A Continuity Architecture for Defense Programs

The Alemian Retention System™ is a U.S.-copyrighted framework designed to stabilize critical billets, preserve domain knowledge, and support uninterrupted execution across multi-year programs.

Built for operational integration:

Overlays existing structures.

Requires no change to authority or workflows.

Preserves operational tempo.

ARS addresses continuity failures before they become schedule risk.

VALUE FOR PRIME CONTRACTORS

Strengthens production cadence and delivery reliability.

Reduces workforce-driven schedule exposure.

Supports sustained execution across multi-year programs.

Positioned at the operational and program level.

RELEVANT EXPERIENCE

Briefings address:

Continuity requirements

Stability vulnerabilities

Delivery and sustainment timelines

Designed for shipyards, primes, and industrial-base leadership.

Document Downloads

Entity Profile

UEI: KDPTBD773EA5

CAGE: 177Q9

SAM: Active

NAICS: 541612, 541611, 611430

PSC: R499